Suleyman Kivanc Ekici, MSc. Computer Engineer

Sales Manager, NRM Engineering

April 2025

In today’s fast‑paced manufacturing environment, ensuring product quality without sacrificing speed is more critical than ever. Recent research highlights that while manual inspection remains indispensable for complex, low‑volume items, automated systems offer compelling advantages for high‑volume production. Here’s why and how you can leverage both approaches for maximum impact.

Why Inspection Matters

Every product that leaves your facility carries your reputation. Defects not only erode customer trust but also drive costly recalls, rework and warranty claims. Choosing the right inspection strategy is therefore a strategic decision: it directly affects quality, cost and delivery performance.

Manual Inspection: Flexibility at a Cost

Pros

● Human Judgment & Flexibility: Skilled inspectors excel at nuanced, subjective assessments think cosmetic finishes or irregular shapes in aerospace or medical devices.

● Low Up‑Front Investment: Setting up manual stations typically requires minimal capital; ideal for pilot runs or bespoke products.

Cons

● Error‑Prone & Inconsistent: Fatigue and variability can lead human inspectors to miss up to 40% of defects in some studies.

● Throughput Bottlenecks: A single inspector may only process tens of parts per hour, creating queues on high‑speed lines.

● Rising Labor Costs: Skilled QC personnel command competitive salaries, and staffing shortages can further inflate costs.

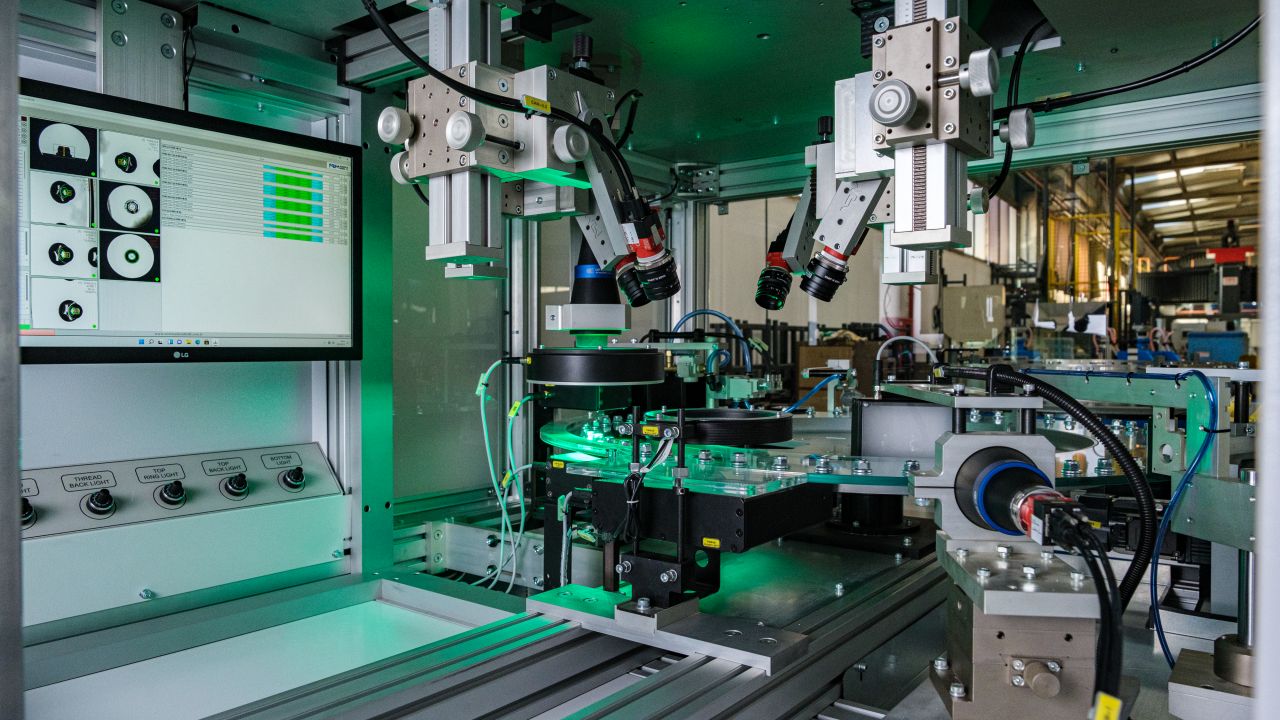

Automated Inspection: Throughput and Consistency

Pros

● Speed & Capacity: Modern vision‑based systems can inspect hundreds or even thousands of parts per hour, reducing manual workload by up to 75% in applications like automotive battery pack quality checks.

● Consistent Accuracy: Machine vision and AI algorithms apply the same criteria 24/7, virtually eliminating human variability.

● Long‑Term ROI: Although initial setup can be costly, reduced labor, fewer defects and lower rework translate into rapid payback—some medical‑device manufacturers report multi‑million‑dollar annual savings.

Cons

● High Up‑Front Cost: Cameras, sensors, lighting and software licenses require significant capital, which can deter smaller operations.

● Technical Expertise Required: Integrating and maintaining automated systems demands skilled technicians and ongoing calibration.

● Complex Part Limitations: Highly variable or textured parts may confound cameras at least until algorithms are trained on thousands of samples.

Throughput in Focus

Ultimately, throughput or how many parts you can inspect per hour often dictates which approach makes sense:

● Low‑Volume, High‑Complexity: Manual inspection shines when volumes are modest and each part demands careful, human appraisal.

● High‑Volume, Routine Checks: Automated systems excel at continuous, fatigue‑free operation. In one manufacturing line, automated optical inspection cut cycle time by 20% and redeployed nearly 20% of QC staff to higher‑value tasks.

Many leading manufacturers now adopt hybrid models: automated vision systems screen “good” parts at blistering pace, while flagged or suspect items are routed to skilled inspectors. This fusion delivers both speed and reliability.

Making the Right Choice

1. Assess Your Volumes: If you’re inspecting thousands of identical parts daily, automation almost always wins.

2. Map Your Defects: Complex, aesthetic, or one‑off products still benefit from human eyes.

3. Pilot & Scale: Start with a pilot cell validate throughput gains and ROI before full‑line rollout.

4. Train & Upskill: Invest in operator training for both manual best practices and automated system upkeep.

Conclusion

While manual inspection remains essential for nuanced judgment calls, automated solutions deliver the consistency and throughput today’s high‑volume manufacturers demand. By thoughtfully combining both screening with machines and adjudicating with humans you can achieve optimal quality, reduce costs and keep your production lines humming.

What’s your experience? Have you implemented a hybrid inspection strategy? Share your successes or lessons learned below!